Die diesjährige Test Convention findet am 24. und 25.04.2024 in einem neuen,…

Für Entwickler und Testingenieure mit Leidenschaft für Automobile veranstaltet…

Die Elektronikfertigung hat in den letzten Jahren eine außergewöhnliche Entwicklung…

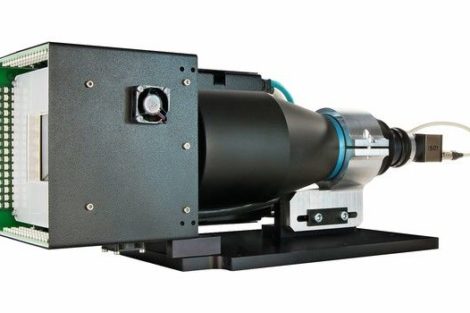

Mit dem MultiEyeS plus bietet Göpel electronic ein leistungsfähiges automatisches…

Mit der neuen Generation des MultiEyeS plus präsentiert Göpel electronic eine…

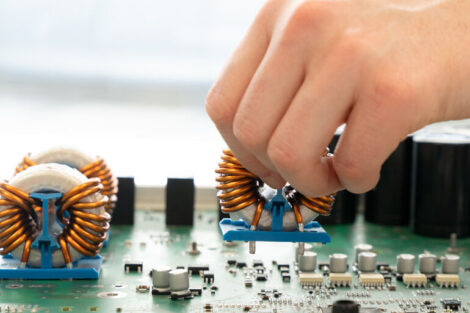

Be it AI-supported inspection programme creation or AI classification of pseudo-defects…

Inspektion und Qualitätssicherung, Test und Programmierung, von SMD bis THT:…

GÖPEL electronic präsentiert mit dem System Vario Line · 3D SPI eine innovative…

Ob KI unterstütztes Erstellen von Prüfprogrammen oder KI-Klassifikation von…

GÖPEL electronic informiert, wie mit Lösungen den kommenden Anforderungen in…

GÖPEL electronic präsentiert die aktuelle Version 4.9.0 der Systemsoftware System…

In der Elektronikfertigung beginnt die Einhaltung von Qualitätsversprechen bereits…

Eine komplette Wellenlötanlage mitsamt Bestück-Arbeitsplätzen und Inline-AOI…

Göpel electronic GmbH zeigt zur electronica einige Innovationen, wie u.a. im…

„Man sieht nur, was man weiß“ sagte einst Johann Wolfgang von Goethe. In der…

Innovative Technologien aus den Bereichen der künstlichen Intelligenz (KI) und…

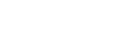

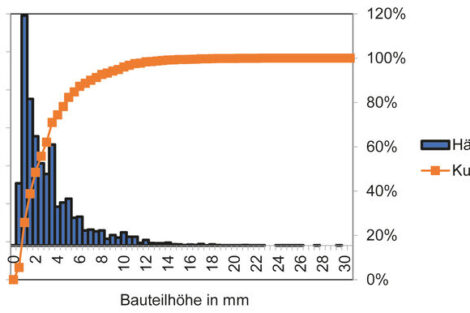

Trotz zunehmender Miniaturisierung der elektronischen Bauteile wird immer noch…

Im Webinar am 22.10.2019 um 10.00 Uhr von Göpel electronic werden Konfigurationsvarianten…

Mit den Test Convention hat Göpel electronic das erste Mal drei Events – Boundary…

Im Mai 1991 gründete Holger Göpel mit ehemaligen Mitarbeitern der Abteilung…

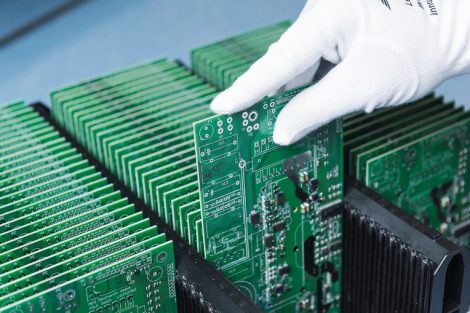

Written off for dead yet still alive and kicking: THT components (Through Hole…

Für zahlreiche Fertigungs-Dienstleister ist dies eine alltägliche Herausforderung:…

Maschinen und Fabriken werden vernetzt, schlauer, „smarter“ – und die Elektronikindustrie…

Vernetzung, Digitalisierung, Big Data, Industrie 4.0 – diese Schlagworte sind…

Seit jeher unterstützt die Göpel electronic mit innovativen Test- und Inspektionssystemen…

After the conversion from leaded to lead-free soldering of electronic components…

Unter dem Motto „Messen mit mehr Blick“ fanden in diesem Jahr die Inspection…

Im Interview mit Andreas Türk, Göpel electronic GmbH über Hard- und Softwarelösungen…

Inspektionssysteme (AOI, AXI, SPI) sind mittlerweile fester Bestandteil in jeder…

Egal ob serielle Flashes (eMMC, I²C, SPI), parallele…

Dieses…